- Total 0 kr

OxyG Drain works great for:

- Removes bad odor in and around grease traps

- Reduces fat and sludge

- Prevents grease buildup in pipelines

For best results, OxyG Drain at evening/ night when water flow is reduced to a minimum. Apply directly to sink drains, floor drains, grease interceptors, or grease traps.

Grease traps almost always smell very bad, especially when emptying/ pump out. This is due to an imbalance in the bacterial flora in the grease trap. Then OxyG´'s bacteria is an alternative.

Another common problem is grease escape, meaning that the grease does not stay in the grease trap for which the grease trap is designed. This is not really a design error but depends on how you mix different fats when cooking together with the fact that the advice for size of grease separator is usually too small. When fat escapes, this means that it takes longer than expected for the fat to separate in the water. Fat or grease to float up and stay in the grease trap. This means that some of the grease flows through the grease separator and ends up in the subsequent sewage system and creates problems in, among other things, liftstation, infiltrations, leach fields, pipes, treatment plants and more.

Wrong bacteria produce hydrogen sulfide (H2S) which creates odors in and around the grease trap. The gas is aggressive towards materials and harmful to humans at certain concentrations.

It is difficult to clean a grease trap if the grease is saponified or hardened. It goes for hot water, flushing car and maybe a hoe.

In the case of sludge or grease escape, this means that the size of the sludge separator / grease separator is usually too small, even if the size of the sludge separator follows the recommendations. The wastewater you produce needs more time to separate sludge and grease in the sludge separator.

There are really only two ways to solve the problem.

- Install a larger sludge separator (especially relevant when a new sludge separator / grease separator is built)

- Increase the rate of decomposition in the sludge trap / grease trap of the organic material with the help of bacteria, which will provide a cleaner wastewater out of the sludge trap

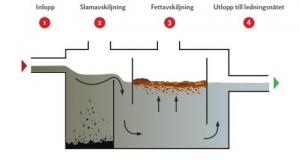

The principe of a grease trap

1 inlet 2 Sludge separation 3 Fat separation 4 Outlet

By using OxyG DRAIN regularly in the grease trap, 95-100% of the odor will be reduced.

The grease in the grease separator becomes soft, easy to suck out for the sludge truck, at the same time as cleaning becomes much easier, which saves time and money. Reduction of sludge and fat will occur.

Through a better biodegradation process, a cleaner wastewater from grease separators also comes, which means that subsequent grease problems are eliminated or greatly reduced.

Dosage: 10 measures / week

The smell disappears in a few days depending on how much grease there is in the separator

It should not smell in a grease trap or when emptying!

When dosing in a sink or floor drain, the pipes will also be cleaned on the way to the grease separator